Bolted connections are often used in critical, safety-relevant places such as bridges, wind turbines, vehicles or machines, where they are permanently exposed to high loads. To ensure the safety of these connections, they require permanent monitoring of the preload force.

Q-Bo® measures precisely and transmits wirelessly

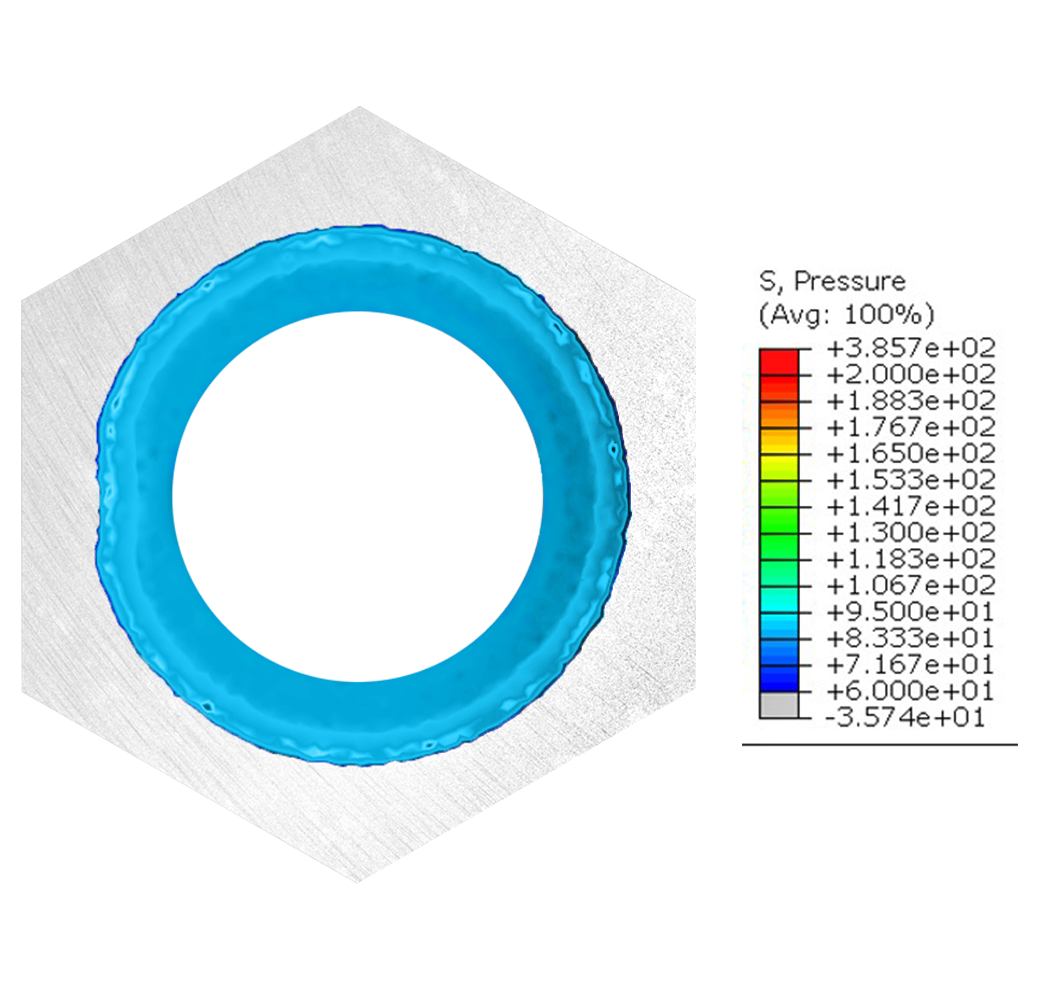

The smart screw connection Q-Bo® enables wireless, self-powered monitoring of the preload force with the aid of a retrofittable sensor system: Using a special pressure and temperature thin film, known as the DiaForce® film, the tightening force as well as the temperature of the screw connection is regularly determined at the assembly location and transmitted to a cloud via a standardized interface.

Fraunhofer Cluster of Excellence Cognitive Internet Technologies CCIT

Fraunhofer Cluster of Excellence Cognitive Internet Technologies CCIT