»Edge Cloud Continuum« – A New Generation of Secure Data Spaces

Want to know how you can use production data securely, efficiently, and in real time – from sensor to cloud? Join the Fraunhofer CCIT at EMO Hannover 2025 to find out!

At Hall 6, Stand B18, you’ll discover the Edge Cloud Continuum (ECC) – an innovative solution shaping the future of (metal) manufacturing. This system intelligently distributes computing power between the edge and the cloud, allowing you to process data in complex, networked production environments securely, sovereignly, and scalably.

What’s the goal? To create a new generation of trusted (edge) cloud infrastructures for industrial applications – all made in Europe. Whether you’re interested in predictive maintenance, AI-driven process optimisation, or secure data spaces for manufacturing, our CCIT approach equips you with the tools for future-ready, digitally connected production.

»Edge Cloud Continuum for Production« – Boost Your Manufacturing with Secure, AI-Driven Monitoring

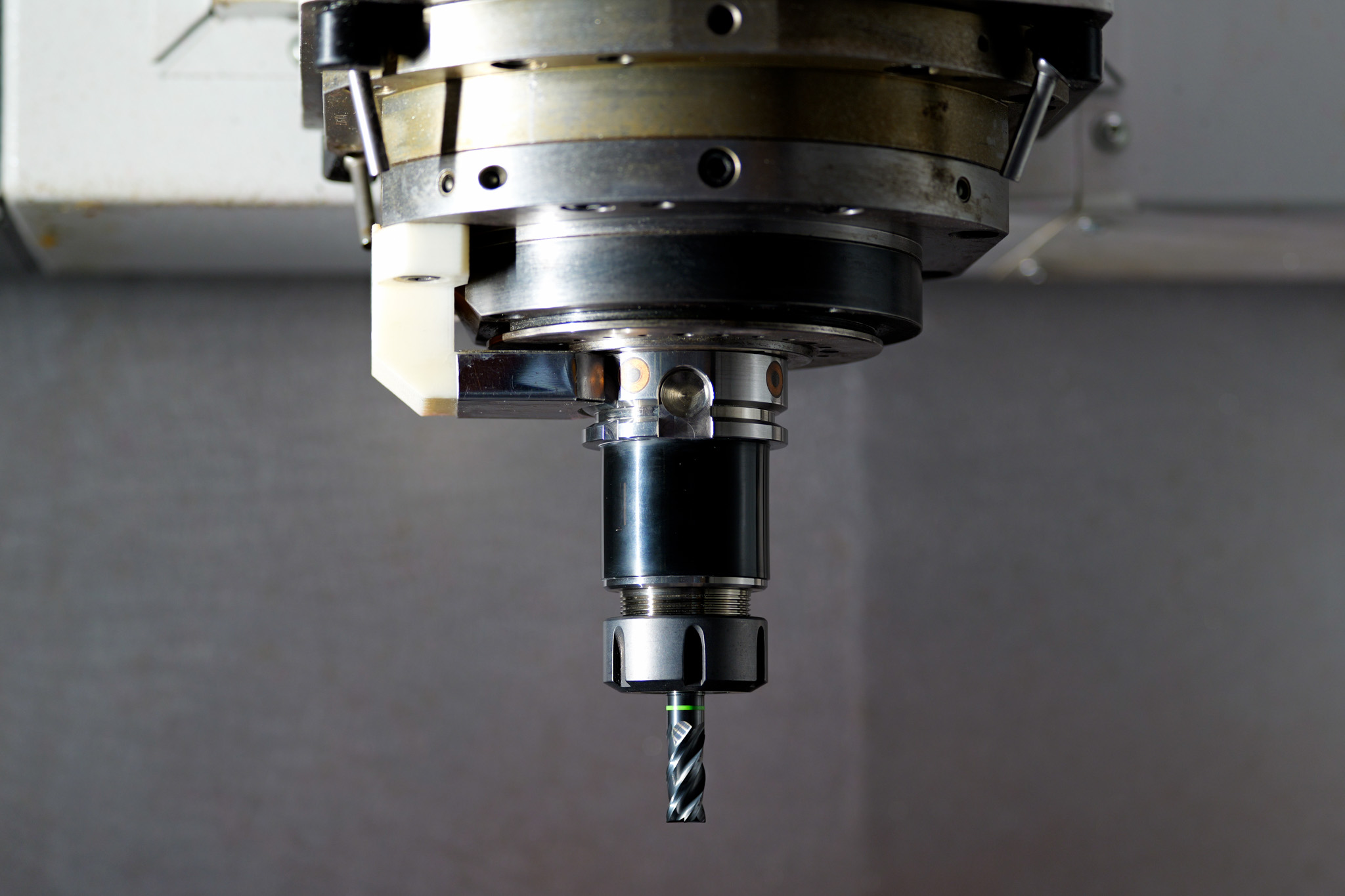

The star of the show at EMO 2025 is our »Edge Cloud Continuum for Production« (ECC4P). The Fraunhofer CCIT invites you to explore a comprehensive monitoring system built on an edge-cloud infrastructure. At an interactive multimedia wall, you’ll get a hands-on look at intelligent, secure, and connected production. You’ll discover how our ECC4P efficiently manages every process stage – from sensor technology and machine-level edge data processing to AI training in the cloud – all while keeping your data sovereign.

Fraunhofer Cluster of Excellence Cognitive Internet Technologies CCIT

Fraunhofer Cluster of Excellence Cognitive Internet Technologies CCIT