Fraunhofer CCIT at EMO 2025

»Edge Cloud Continuum« — Unlock the Future of Metal Processing

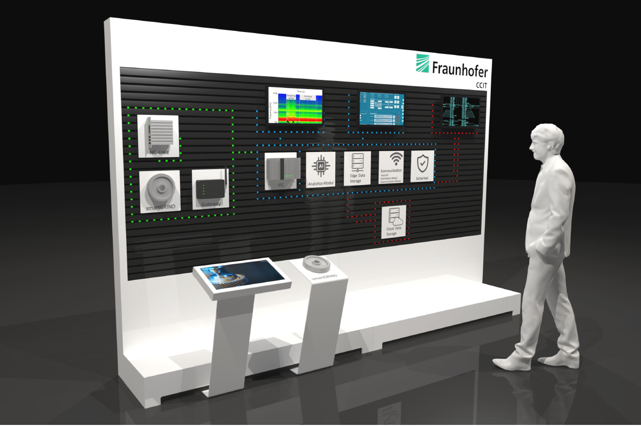

Join the Fraunhofer Cluster of Excellence Cognitive Internet Technologies (CCIT) at EMO Hannover, from 22 to 26 September 2025, at their joint stand (Hall 6, Stand B18), where you’ll see its member institutes — Fraunhofer IWU, IAIS, IMS, and IIS — bring a sovereign digital infrastructure to life for manufacturing processes. Using the Edge Cloud Continuum (ECC), you can combine IoT technologies, secure data spaces, and machine learning to build a future-ready cloud system for many applications. The Fraunhofer CCIT showcases multiple exhibits to show how smart digital infrastructure, combined with advanced production technologies and manufacturing processes, can revolutionise operations.

The digital transformation is reshaping industrial production. Networked machines, AI-driven processes, and data-powered business models unlock new opportunities. To make this happen, you need a secure, sovereign digital infrastructure. The Fraunhofer CCIT delivers cutting-edge solutions such as secure data spaces, trusted edge-cloud architectures, and open-source tools tailored for the manufacturing sector.

Michael Fritz, Head of the Fraunhofer CCIT Office, emphasizes: »The manufacturing sector is bursting with potential. By securely sharing and smartly using data, you can make your manufacturing processes more flexible, efficient, and sustainable. Powered by our scalable solution, you can explore data-driven services and digital business models – all made in Europe.« EMO Hannover is your ideal platform to see how the Fraunhofer CCIT can boost your competitive edge sustainably.

The core of your experience is the Edge Cloud Continuum — your key to future-ready manufacturing. It blends decentralised edge computing with centralised cloud solutions, letting you process data where it’s most effective — for efficiency and cost savings. This delivers flexible, sovereign data processing across networked production environments, from sensors to the cloud to AI applications. The Edge Cloud Continuum enables you to achieve greater efficiency and transform digital value chains.

ECC4P – Power Your Manufacturing with Secure, AI-Driven Monitoring

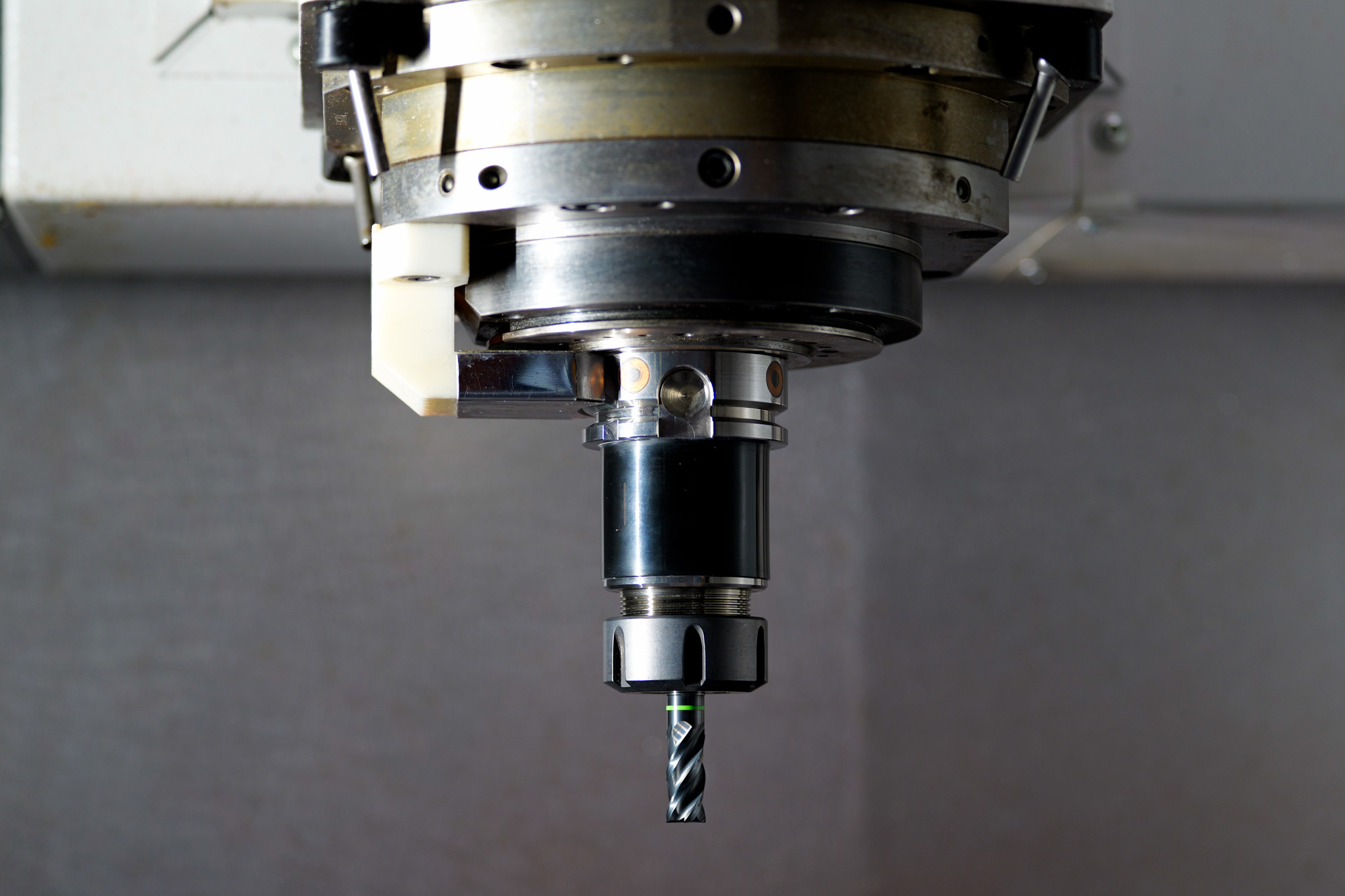

At EMO Hannover, the Fraunhofer CCIT invites you to explore the Edge Cloud Continuum for Production (ECC4P) on our interactive multimedia wall. See how modern cloud and edge technologies enable secure, efficient data processing in manufacturing. Discover practical applications such as milling, drilling, grinding, or forming. ECC4P offers a complete solution for new facilities or a modular upgrade to optimise existing setups.

Alongside ECC4P, discover more applications that highlight the Edge Cloud Continuum’s potential in production. With smartTOOL, integrated sensors and energy harvesting let you monitor processes wirelessly and accurately. smartNOTCH enables real-time monitoring right at the workpiece, spotting tool wear early to ensure component quality.

Michael Fritz explains: »Thanks to ECC4P and its complementary applications, you can unlock the full potential of the Edge Cloud Continuum in production — from tool monitoring to running AI directly on your machine. This lets you build a sovereign, future-ready production process.«

Fraunhofer Cluster of Excellence Cognitive Internet Technologies CCIT

Fraunhofer Cluster of Excellence Cognitive Internet Technologies CCIT